An explanation of Chrysler's part and casting number system:

Written by Brandon Nicholas in 2003.

The following page is copyright www.440source.com

Chrysler used a numerical system to identify every part ever made for every year of vehicle. These numbers are like the holy grail to anyone wanting to restore a car, or learn more about certain parts and when they were used, what vehicles they were used on, etc. The most useful benefit of these numbers is that they allow us to work backwards and find out what other (more common) vehicles the parts were used on. Was that single groove crank pulley for your '70 Hemi Cuda also used on a 1963 slant six? (This is a fictional example only....don't go running to the junkyard and take every 1963 slant six pulley you find) The way to find this interchange information and "work backwards" so to speak is by using Chrysler's "Parts Catalogs."

Every year Chrysler's "Catalog and Publications Dept" would put out a "Parts Catalog" (sometimes multiple years were condensed into a single catalog) which were sent to the dealers so they could look up parts for service mechanics and customers. One catalog was issued for passenger cars and a separate one for trucks. They were usually about five inches thick and came in hard plastic blue binders. Because only dealers could get them, the originals are not very easy to come by anymore. Fortunately, reproductions are available (or you can occasionally find the originals) at Faxon auto literature. 800-458-2734. They also have tons of other great Chrysler literature such as owners and service manuals, and even the original dealer sample books that were used to help customers pick the paint colors and interior fabrics.

Now on to the numbers themselves: Chrysler's part numbers are date specific, and if the numbers are broken down, it is possible to determine the year that the part was first put into use. Note that the number only tells you the FIRST year it was used. If the part continued to be used for five years, the number will not indicate this. The numbers will almost always be a 7 digit number. For clarity and ease of writing, this seven digit number is usually broken up into two parts, a prefix and a suffix, similar to a seven digit phone number. However, the way it is split up is with the beginning 4 digits first (the prefix) and then the last three digits (the suffix) which is a mirror image of how a phone number is divided.

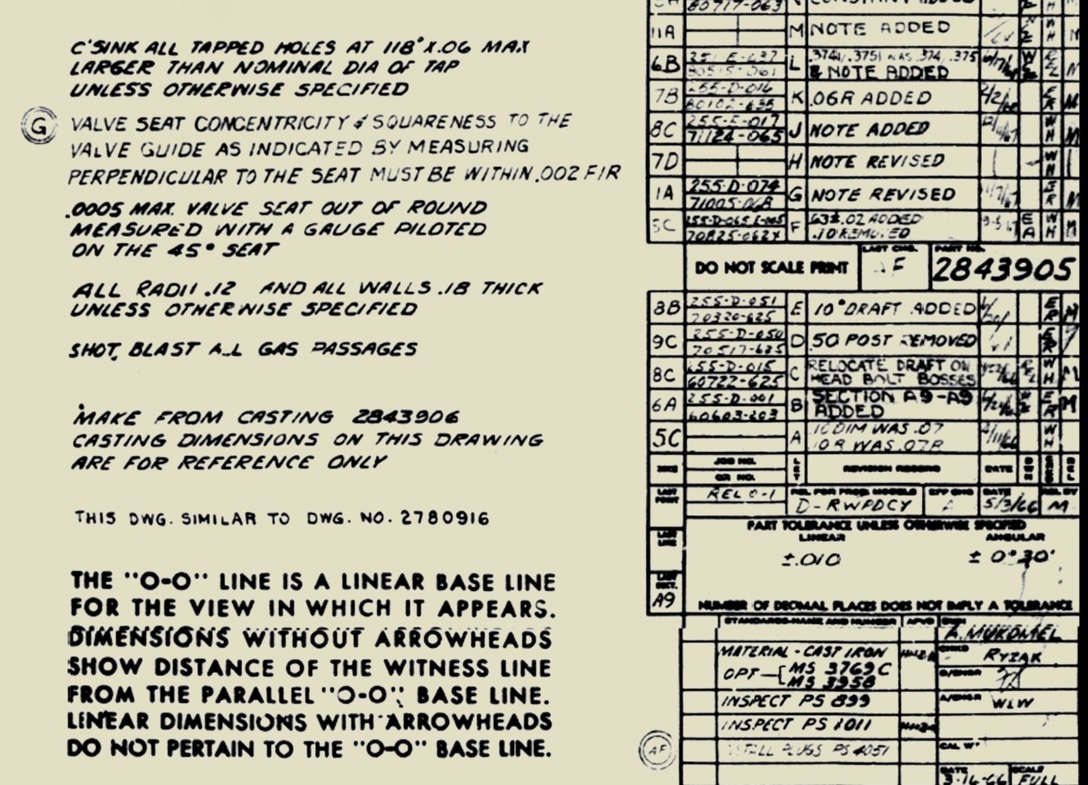

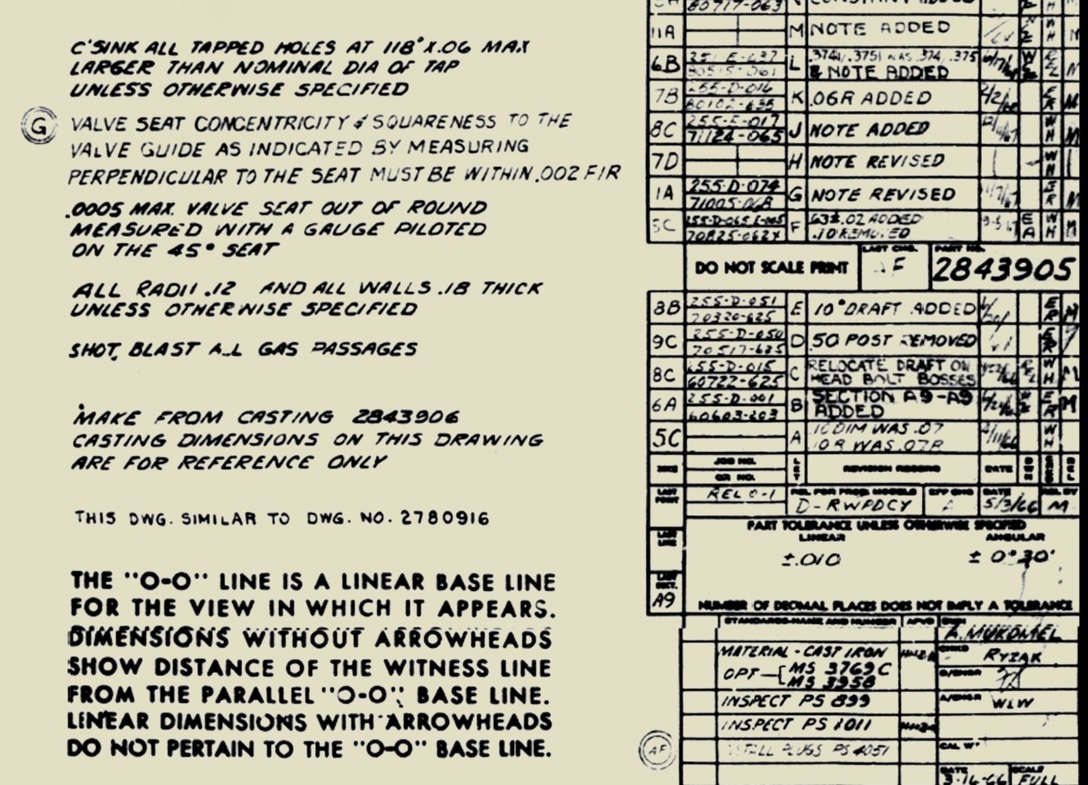

A typical part number might be a cylinder head: 2843905. The first digit represents the decade. A "2" in this case is the 1960's. Part numbers starting with a "1" would be from the fifties. The second number represents the year. So in this case "8" would be 1968. This is why most big block parts will never start with a prefix earlier than 17 or 18, as they were first designed and released in late 1957 for the 1958 model year. This date system holds true for almost all part and casting numbers up until about 1969.

During 1970 for some reason (except for a few 30XX parts) the 30XX-33XX prefix numbers were skipped and part numbers started at about 34XX, so most numbers for 1970 and 71 will begin with 34 or 35. An example would be part number for a 1971 440 4 barrel intake manifold: 3512 502. The 36XX prefix started in late 1971 and was used through most of 1972. 37XX started in late 1972 and was used through most of 1973 and 1974. 38XX started in late 1974 and was used mostly in 1975. 39XX was very limited and used in 1975, and then the numbers rolled over to 4000 prefix. One famous part that began to be used in late 1975 is the 4006 452 heads. Numbers seemed to stay in the 40XX and on a more limited basis, the 41XX prefix through all of 1976-77-78 to the end of production.

The part to casting number dilemma:

With many cast iron engine parts, the "part" number which Chrysler used to identify a part on paper and for administrative purposes is not the same number that was cast into the part itself. This was the "casting number" which is usually a very similar number except the ending digit is typically off by a couple places. One example is the famous 2843 "906" heads. They are Chrysler part number 2843 905. On the original Chrysler drawings or "blueprints", they specify "Make from casting #2843906" (see below.)

So there are several reasons why the part number can be different from the casting number.

A common reason is when parts were sold from Chrysler as an "assembly." The part with the casting number would be listed in the assembly, however the part number of the assembly itself would come before or after all the previous parts in the assembly were listed, causing the part number to be anywhere from one to a few digits off. Many parts that would not at first seem to be an assembly actually were. Take an oil pan for instance. This would seem to be a single part with a single number. However, when Chrysler sold an oil pan, they included the gasket and the drain plug. Now you have an assembly of three parts. Other parts such as a connecting rod must include bolts & nuts, a timing cover must include a seal and gasket, etc, etc.

Sometimes several part numbers were a variation of one part, with the same casting or stamping number. Oil pans are a good example of this. Common Chrysler oil pans are stamped with numbers we recognize, such as 187, 699, 402, etc. Often, some of these pans had baffles welded inside (usually on high performance cars), while others didn't. Each version of the oil pan would require a different part number, even though the stamping number on the pan itself was the same.

I've also seen parts which are painted different colors, and have a different part number for each color, even though the part itself is exactly identical.

Another situation can occur when a part is used over a long period of time, and the part number is changed by Chrysler (maybe for price increases or other administrative reasons) while the casting number is left alone. Take the standard 440 "LY" rods, casting number 1851535. First introduced in 1959 with a 1851533 part number, this was changed in about 1965 to 2406770 and again in about 1975 to 4027096, while all this time the part itself remained completely unchanged, original casting number and all.

Another interesting fact is that occasionally Chrysler would cast the part number instead of the casting number into a part (I have seen this on intake manifolds, never on blocks or heads,) and often the location of the casting number will change, or be in a different location on the part, even among identical parts of the same casting number and same year. This usually occurs with intake manifolds as well and sometimes water pump housings.

While we are on the subject of casting numbers, often there will be what is known as a "dash number" after the casting number. A 1968 440 block, for instance, might read 2536430-12, or sometimes there will just be a space, such as 2536430 12, or sometimes 253643012. While 2536430 would be the casting number, the -12 would be the tooling number. In order to keep up with the volume of castings needed for production, Chrysler often had multiple sets of tooling. The tooling are the "molds" and core boxes used to make shapes out of sand, which is then used to direct the hot iron as it is poured into shape to make the part. The dash number was used to keep track of which set of tooling was used to make a specific casting. In addition, after so many "pours" the tooling gets worn and needs to be reshaped or reconditioned. So theoretically, higher numbers will be later dates and have any casting improvements incorporated into them. The only problem with this theory is that engines were produced in such volume that many many different sets of tooling were used concurrently to meet the necessary output. So while some may have lasted for quite a while, (in which case you will find later dates with earlier revisions) some got worn quickly or damaged and needed to be revised after a short time. So while in some cases, parts with later numbers may include some improvements the earlier parts may not have, on a practical level, it means nothing as far as the quality of the piece. In other words, don't waste your time looking for an early or late tooling number. Blocks, heads, water pump housings and many other cast parts have tooling numbers as well. Usually when there were major changes or improvement made, they would change to a completely different (later) casting number.

Another thing to keep in mind is that tooling revision numbers have absolutely nothing to do with core shift, which is when the core molds move around as the cast iron is poured. That will vary depending on how much the molds moved in the specific piece (usually engine block) you are talking about, and the only way to tell if there is enough material in the cylinder walls is to sonic check the specific block you are going to use. As you probably learned from our "Everything you've ever wanted to know about engine blocks" page, (and if you haven't read this page yet, you should) there are no thinwall blocks, however we have found core shift to be less prevalent in the later blocks, perhaps due to improvements in casting technology over the two decades the engines were in production.

![]()

![]()

All website content copyright 440 Source

(775) 883-2590