The 440 Source story…

The story of 440 Source starts with a 9 year old boy. The year was 1985. One nice Southern California summer day this boy decided to take his bicycle for a ride around the block. After turning a few corners, he suddenly came across someone’s 17 year old used car parked in their driveway. The car had a flat tire, upholstery that was split apart with foam showing in multiple places, and some surface rust on the fenders and quarters. But this wasn’t just any old car. This was a 1968 Dodge Charger. The boy could not believe his eyes. It was the most beautiful looking car he had ever seen. He laid his bike down on the grass and just stood there and stared at it. A good 30 minutes must have gone by.

Finally, he rode home and proclaimed, “This is the car I will be getting when I turn 16!” The response from his parents was predictable: “Suuuureee you will. By then you’ll want a Jeep or a pickup truck, VW Bug, or some “normal” car that most teenagers drive, not some 24 year old piece of junk.”

As the summer days went by, every day he would ride his bike to go see the Charger. Then, one day, suddenly, it was gone forever.

Fast forward to 7 years later, and not a single day went by that the boy did not dream of the day he turned 16, when he would be able to own and drive his own 1968 Dodge Charger. At 15 ½, he started searching high and low. Of course, almost nothing was online back then, so he picked up Hemmings Motor News and Auto Trader magazines at the newsstand. After test driving a couple cars that were in such bad shape they barely ran, he came across an absolutely cherry black on black factory R/T 440 car. He was 2 weeks away from turning 16. It was in perfect shape and everything a 16 year old boy could dream about. Except for one problem, they were asking $7500 for it. Back in 1992, this was an absolutely insane amount of money for a high school kid, even though today the car would be considered the "deal of the century" at 10 times that amount. He made an offer with all the money he had saved, took an advance on his college fund, plus called in a gift/loan/promise of servitude from every family member he could sucker into, and managed to scrape up the $7500 to purchase the car.

As is the case with many 16 year old boys, it probably wasn’t 2.8 milliseconds after buying it until the next logical thought came along, “How do I make it faster?” So, he decided to stop off at the local speed shop, “Super Shops” on the way home from picking up the car. He knew absolutely nothing technically about cars or engines at this point. The salesman there told him, “You should start with a high flow air cleaner.” So they bought one of those and went out to the parking lot, where the salesman was nice enough to install it. The only problem is that the air cleaner came with a “universal” 8 inch long mounting stud. And nobody noticed this, so when the salesman closed the hood, the stud punched right through it. And so began the journey.

After that, the boys single life purpose became about making the car faster. He went to the library and read every book they had on auto mechanics and engine servicing. He hung out with any local mechanics that would let him, trading any knowledge they would offer in exchange for helping them with menial tasks like scrubbing parts clean in the solvent tank.

He dreamed of being technically proficient enough to be able to disassemble a Charger, lay out all the parts on the floor, and then put it all back together again. He went to the local vocational school after high school every day and took every automotive class they offered. Engine rebuilding, body work, electrical, etc. Once he finished all these, he went to the local community college and took welding and metallurgy classes there.

Once school got out, he worked summer jobs valet parking cars to get any money he could. As soon as a paycheck came in, it was gone in seconds. After the air cleaner came a hotter camshaft, then headers, then a shift kit, performance distributor, fatter rear tires, and on and on. Trips to the race track became common and he started bracket racing the car.

The boy and the car - About 1992

Then, one day, the engine started knocking. It had spun a bearing. The boy (now about 17, this was 1993 or so) went to the local junkyard and found there were many large luxury boats (Imperials, New Yorkers, etc) with 440’s in them in great condition just waiting to be pulled out and brought home for just $99.95!

After switching out the 440 short block, he had an extra set of heads, crankshaft, rods and engine block from the old engine just taking up space. One day he was hanging around at the local speed shop down the street, known as P.A.W. or “Performance Automotive Warehouse.” If you recall this place, they used to have a huge “phone book” type black and white catalog with every performance part you could imagine. Remember, this was completely pre-internet. One of the things they had just started offering was a “440 Mopar Engine Kit.” They would essentially rebuild a 440, and sell it as a kit with new pistons, rings and bearings, and other new parts substituted when they were available. And you could “upgrade” certain options, such as the camshaft, etc.

The boy asked P.A.W, “Would you happen to need a 440 block, crank and heads to use in one of your 440 Mopar kits?”

Their response? “Hell yeah we do! How many can you get?” And a light bulb went off. After some negotiations, they said they would pay $250 for a block, $150 for a crank, $75 per set of rods, and $100 per set of heads. That’s $575 for an engine that could be bought at the junkyard for $99.95.

The next day he went out and bought a 1971 Crew Cab Dodge truck. He searched up every junkyard in Southern California, from right on the southern border with Mexico, all the way up to the middle of the state. He bought a thomas guide and mapped out the most efficient routes to hit as many junkyards as possible. He stayed at cheap hotels and sometimes made 2 or 3 day trips out of it. He found he could pull 4-5 engines a day if he got there right when the first junkyard opened, and was just finishing up as the last one was closing.

This went on for a few months. But it was hard work, even for an 18 year old. Junkyards have those manual engine hoists. You have to pull the engine out with a chain, and then push the engine and hoist together (easily over 1000 pounds) all the way to the front of the yard to load it. One time, towards the end of the summer, he got heat stroke and was fighting a horrible headache and throwing up for several hours in the junkyard parking lot.

It was at this time, he noticed something. In the “back lot” of the junkyard, where it says “Employees Only” there was a huge forklift ripping apart an old motorhome. After it destroyed the body, it ripped out the engine and threw it in a pile. By this time, he knew the engine. He knew every line and curve of it. Every bracket and bolt. It was a 440. In fact, the pile it was thrown into was a pile of 440’s.

He tried to go into the back area to investigate, but they wouldn’t let him in. As he was leaving, he saw an older man entering with a hard hat and a reflective vest that said “Core Buyer” on them. So he left, and got some sleep. The next day he went into a uniform store, and bought a hard hat and reflective vest just like the man had. He bought some lettering and stuck it on so it said “Core Buyer.” The next day, they let him in and he met with the junkyard general manager. He asked about the “pile of 440’s” and the manager said they mostly sell them for scrap, (about $25 at the time) and if he wanted to buy more than a few at a time, he would sell them for $75, and load them for free with the forklift.

Next stop, a used heavy duty flatbed trailer! He hooked his new trailer up to the ’71 Crew cab Dodge, went straight to the junkyard, and they loaded it up with 440’s. Chances are, if you bought a 440 Mopar kit from PAW anytime during the 90’s, this is where it originally came from. This went on for a while longer, but tearing junkyard engines apart all day is hard, dirty work. The boy wanted to make things fast, not be tearing apart old greasy engines all day long for years on end.

Pictures of the early days - Engine blocks in teardown

So he decided to move to Houston, Texas and enroll in the world famous School of Automotive Machinists. This was the only school in the country (at the time) that offered an education on all aspects of high performance engine building. There was a cylinder head program and an engine block program. He took both, learning how to fully machine every part of an engine: Block boring and honing, line honing, surfacing, rod reconditioning, engine assembly... And in the classroom he studied camshaft design, cylinder head porting, airflow and fluid dynamics. In the evenings he got a job at a local chassis shop and worked on subframing and back-halfing race cars. They were long days. He would go to school all day, and then work at the chassis shop until 11pm or midnight, almost every night. After a year in Houston, he moved back to Southern California and started up the engine buying again.

Except this time, he started branching out. He found that most of the motorhome 440’s he was buying looked almost brand new inside. The motorhome would leak, and rot inside, or be left in a field and get infested with rats, and someone would sell it to the junkyard for next to nothing (or nothing.) By the time he got the engine, it might have 20,000 original miles or less. On 95% of these engines, you could still see the factory crosshatch pattern on the cylinder walls.

Working out of his garage, he started carefully disassembling these engines, cleaning and inspecting them and then re-assembling them with new gaskets and a fresh paint job, etc. He bought an engine run stand and would test them and make sure they were like new in every respect. He would sometimes add performance camshafts or port the cylinder heads to increase their horsepower and sell them as factory low mileage engines.

Pictures of the early days - Cylinder heads in the garage

Pictures of the early days - Engine Parts Storage - Intake Manifolds, Water Pump Housings, Oil Pans, etc.

Pictures of the early days - Short Blocks

Not long after, he got word that a cylinder head machine shop in Detroit was going out of business. He arranged to buy the whole shop for pennies on the dollar. He hooked up the trailer and drove out to Michigan to pick it all up. The shop included a Sunnen VGS-20 seat and guide machine, a Peterson surfacer and a Superflow 1020 flow bench. He set up all these machines (still in the garage behind his house) and started offering Big Block Mopar only cylinder head porting and machine work.

Pictures of the early days - The very first Cylinder Head shop - Out in the garage.

Pictures of the early days - The very first Cylinder Head shop - Out in the garage. That's a Peterson Surfacer on the left, a Sunnen VGS-20 Seat and Guide Machine, and a Superflow 1020 Flowbench at the end of the row.

One of the suppliers he used for buying cylinder head hardware such as valve seals, etc, also happened to be a sales rep for a lifter company called Stanadyne Lifters. He said, "Hey, I can sell you these “trays” of 117 Mopar lifters, and if you can just repackage them into sets of 16, you can probably make some money on them."

Down the street was a regular automotive machine shop he used to have do odd jobs. He told the owner of the shop he was thinking about starting a business selling ONLY Big Block Mopar parts, and asked if he had any advice.

“YOU'RE GOING TO TRY TO SELL ONLY BIG BLOCK MOPAR PARTS!??!” The guy laughed. “You’ll be out of business in two weeks!”

By this time it was 2003, and the “boy” was now 27 years old. He bought a few trays of lifters, put them on the coffee table, and re-boxed them into sets of 16.

This couple dozen sets of lifters repackaged on the coffee table by hand was the start of 440 Source.

Throughout the following weeks and months, he learned about web hosting, bought the domain of www.440source.com, and setup a website. He bought a digital camera and started taking pictures. After the lifters, came oil pumps, gaskets, cams, valve covers, and on and on and on.

This was right when budget priced “imported” parts were starting to come onto the market. But at these early stages, the people making them had no idea WHY they were doing what they were doing. It’s not that the equipment they were manufacturing them with wasn’t accurate, they just didn’t know how to design them correctly, or what type of material (steel) should be used in specific applications. He tried buying an imported harmonic damper from a popular brand name (at the time.) Everything about it was nice looking but made to incorrect specifications. The bolt circle didn’t match the pulley correctly. The center bore was too tight on the crankshaft. The numbers were printed upside down. Even the outer diameter of it was too small. The manufacturer had never even seen a 440 engine in their lives. They knew HOW to manufacture, but they didn’t know WHAT to manufacture.

Still being active in the used 440 parts business, he had crates full of hundreds of original factory Chrysler parts to inspect, measure and test as necessary. He found the damper manufacturer, designed his own version based on original Chrysler parts with CORRECT dimensions that would actually fit and work correctly for its intended use, and had a batch made. They sold like hotcakes. People were so glad to have good, useable parts at a fraction of the price that they had been used to paying.

While he tried first to make everything possible by local manufacturers, and then as a second choice by any factory in the lower 48 that could provide a quality product for a decent price, he found there are some items that are just not cost effective to make in the states. That being said, 440 Source still makes well over 50% of its products in the USA, a ratio much higher than most manufacturing companies.

Because of the unique experience gained in the early years tearing down, detailing, researching and cataloging thousands of core 440 engines, he was able to write several informative engine articles on the 440Source.com website, which are now well known all over the internet as “THE” resource for verified facts on the Big Block Mopar engine.

And over time, using the education and experience gained from the School of Automotive Machinists, he was able to custom design and manufacture from scratch nearly every part that goes into a Big Block Mopar engine. This also helped to “re-issue” many older parts that had been previously discontinued by many other suppliers, making them not only available once again, but available at a good price!

Starting with the more mundane, such as the stamping of oil slingers and the machining of fuel pump pushrods on the centerless grinder, and later undertaking the more challenging such as designing and casting their own aluminum cylinder heads, 440 Source grew over the years and built up a vast network of suppliers and manufacturers, including metal casting and stamping plants, rubber and silicone molding plants, laser cutters, heat treatment facilities and much, much more.

Combined with being a dealer for some of the best names in the business, such as Trick Flow, Comp Cams, Clevite, Edelbrock, Howards Cams, ARP, Total Seal, etc, the company has evolved into the product of decades of real world experience with the big block Mopar engine. They now offer over 700 different unique Big Block Mopar items, and keep in stock hundreds of thousands of parts in their 10,000 square foot warehouse in Carson City.

Pictures of the early days - Moving into our first 10,000 square foot shop in 2006. Quite an improvement over the 3 car garage setup shown above.

As the business expanded, they bought a Freightliner rig and started doing the Mopar show circuit. They went to Chryslers at Carlisle, The Spring Fling in Southern California, The Mopar Nats at Columbus Trail in Ohio, and Mopars at the strip in Las Vegas, among many other smaller shows.

Pictures of the early days - One of our first show displays at Mopars at the Strip in Las Vegas - About 2008

Pictures of the early days - Brandon giving a lecture on Stroker Kits at Chryslers at Carlisle - 2007

Over the last two decades, 440 Source has sold over 2.5 million pounds of Big Block Mopar parts. That's enough parts to fill a convoy of fully loaded semi trucks about a mile long.

Our warehouse is like a Mopar supermarket with rows of Big Block engine parts from floor to ceiling

440 Source's current warehouse stocks over 161,000 Big Block Chrysler parts.

The “boy” in this story is Brandon Nicholas, the founder and President of 440 Source.

Brandon at SEMA in 2022 next to the new 1968 Charger based vehicle that Mopar will be releasing sometime in the next few years.

For us Mopar isn't just a brand, it's a lifestyle. Brandon has owned dozens of classic Mopars over the years. Chargers, Superbees, Road Runners, Darts, you name it. He's owned and daily driven Dodge trucks of every generation, and even Dodge Travco Motorhomes.

But of course, no one person could be responsible for building all that on their own. A huge part of 440 Source’s growth has been due to the efforts and enthusiasm of their employees. The vast majority of 440 Source’s employees stay with the company for many many years.

Kim (Ken) Burns worked as our Sales Manager for over 13 years. Unfortunately, he succumbed to cancer a couple years ago. He was only in his 50’s, but he absolutely loved his job. He came into the office every day until the very end. Until he was so weak he literally couldn’t walk in the door. About 6 months before the end, when things were looking grim from a health perspective, Brandon sat down with him and said, “Why don’t you go travel the world and enjoy the time you have left? Are you sure you want to be sitting behind a desk, talking to people about building engines all day long?” He said, “This is what I was born to do. Helping these guys and sharing my knowledge and love for engines, I’ll be here doing this until my last breath.” And he literally was. We will all miss him, and unfortunately losing him was a big loss for both the company and the Mopar world.

Shown here at the Las Vegas "Mopars at the Strip" show in March 2009 is Kim (Ken) on the right, with Brandon on the left.

Ray Bolton was our shipping manager for many years. Unfortunately he passed away in 2018. Ray served in the United States Army as a machine gunner in Vietnam, wielding an M-60 in active combat. After returning home, he developed a love for 1970-74 Challengers. One of his favorite things was the Challenger he restored and took to shows almost every month. He had a whole room in his house full of trophies the car won at shows. For many years he kept our shipping department running smoothly and enjoyed being around the Mopar world and parts daily.

|Ray Bolton (Above) in front of his Orange Challenger.

Ray Bolton (right) and Brandon (left) meeting with Vic Edelbrock at SEMA in 2010.

Terry in his office

Terry has been with the company since 2016, and has over 12 Mopars, including a 1972 Challenger, a newer Avenger, several Dodge trucks, a Dodge van, and several other classic Mopars. Terry has decades of experience working at many different automotive machine shops over the years, and he also does all our engine balancing and cylinder head machine work. He is also an experienced body man and is well versed in body panel replacement and automotive paint and finishing. You can email Terry directly at: terry@440source.com

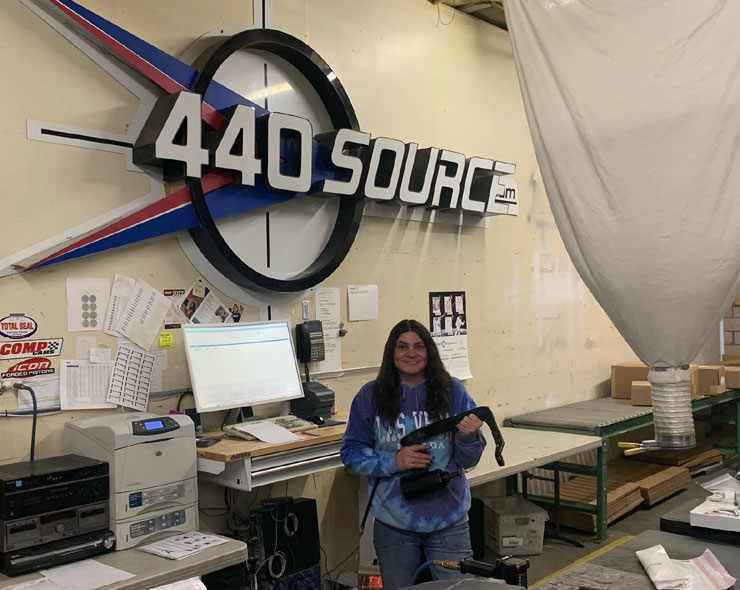

Maria at our packaging station in the warehouse

Maria handles our receiving and other warehouse related duties. Maria drives a Jeep, so she's still part of the Mopar crew.

Throughout the Covid years, we are proud to say 440 Source never closed down for a single day. We made HUGE investments to keep all our parts in stock during a time when many business tell you you're lucky if you get it in 8-12 months, if ever. People will order our Complete Engine Packages and within 24-48 hours, over 100 parts will be heading their way on a Fedex truck without a single backorder. That's almost unheard of, especially in this day and age. We do business by simple principles. We don't backorder or drop ship anything. Except for the rare exception of custom made parts, if it's not sitting on our shelf and ready to ship out to you the same day, we WILL NOT take your money. Even if you want us to. And it's been like that since the first day we started doing business, over 20 years ago.

While we may not be curing cancer here, we still feel like it's important and rewarding. When people send us pictures of the engine they just pulled out together with their son or grandson, or draw us a card in appreciation for the help we gave them with their build, that makes it all worth it. These cars are works of art. They bring us back to a time when things were simple and well made. Or maybe a time when we were younger and had our whole lives ahead of us.

To the average person, we might be selling blocks of machined aluminum. To those living the MOPAR LIFE, we are selling the adrenaline coursing through the veins of that high school kid, when he stomps on the gas and leaves that other kid in the Mustang several car lengths behind in a cloud of dust. We are grateful to be able to help people re-live that joy.

A thank you card sent to us by a customer and their grandson.

We have several new and exciting parts currently in the works. Join us as we continue to grow and get better at what we do.

We’d like to thank you for reading our story, and for any business you may have done with us or might choose to do in the future. We know we are only still around because you choose to vote for us with your hard earned dollars.