Chrysler's Trenton Engine Plant:

Written by Brandon Nicholas at 440 Source.

All Big Block Mopar engines for U.S. production were built at Chrysler's Trenton Engine Plant in Trenton, Michigan. Chrysler started groundbreaking on the plant in February of 1951 and engine production started in Fall of 1952.

Major building additions were added in 1964, 1967, 1969, and 1977. The plants grounds are 136 acres, of which 47 acres (2,054,273 square feet) are under roof, or interior (factory) space.

The Trenton factory employed an average of about 4,560 people and made big blocks and slant 6's.

Putting up the new sign in 1966.

Thoughout the building, there were 41,800 feet (or 7.9 miles) of conveyors carrying stock and parts to various departments.

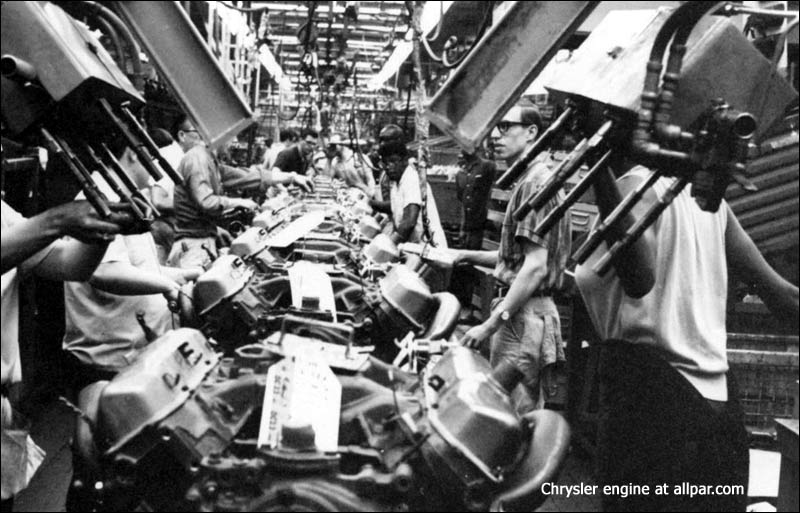

The production lines consisted of six engine block lines which were 1200-1600 feet long, and 5 cylinder head lines which were 435-450 feet long. From there, engines went into two different assembly lines which were 600-900 feet long.

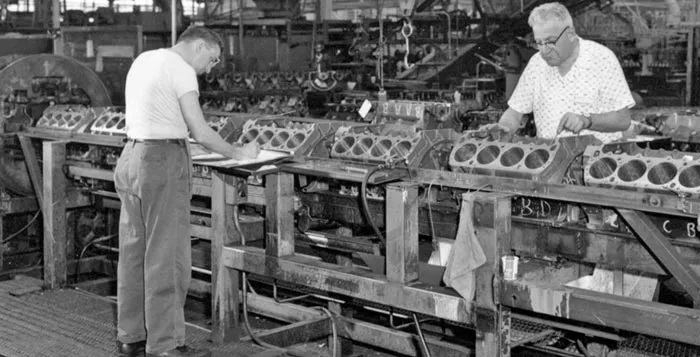

Here you can see engine blocks coming out of the block department.

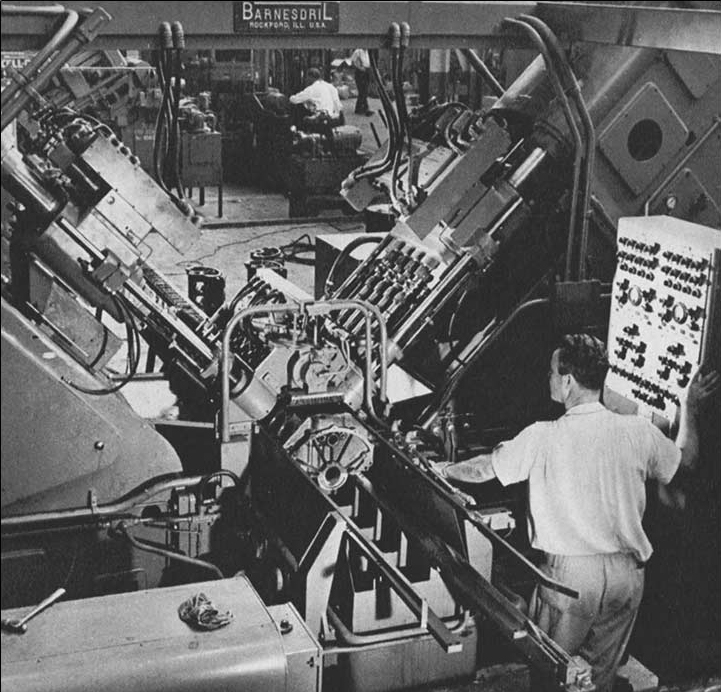

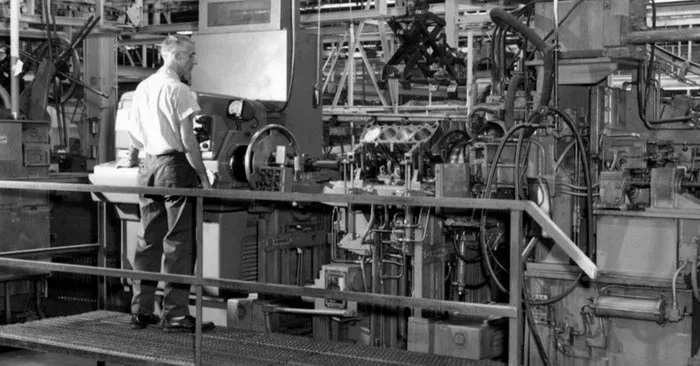

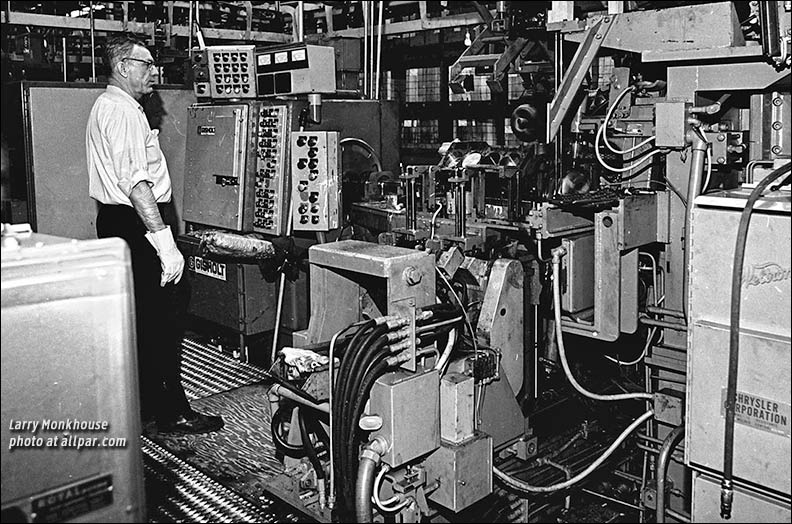

Cylinder bore machining was done in all 8 holes at the same time by this massive machine. It was not particularly accurate, which we will explain more about later in the piston section.

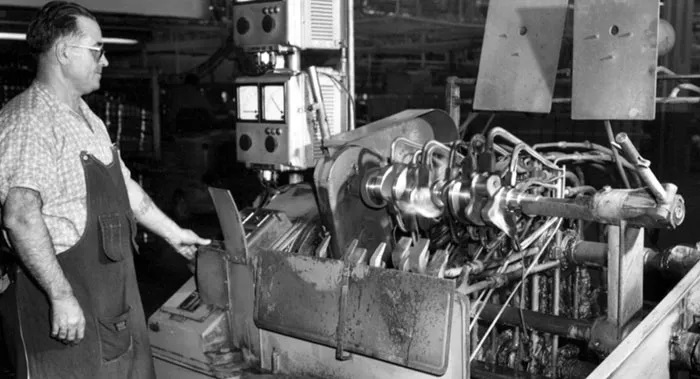

Crankshafts had to be heat treated, ground and balanced in the crankshaft department.

And finished cranks were prepped for installation by installing the flexplates first.

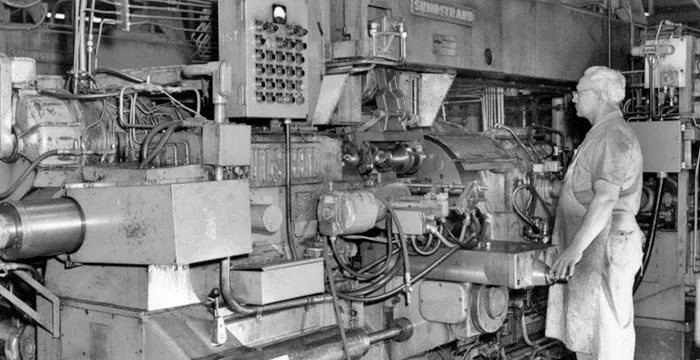

The cam grinding line has quite a few machines, which were all run by hand. The Trenton plant in total had 2,047 manufacturing machines of 216 various different types.

Pistons came down the line as well.

.jpg)

Pistons were grouped according to final size. The way these sizes were identified were with letters, A-E. You can see the sections in the background of the picture above where pistons are grouped according to letter type.

Because the cylinders could not be bored accurately, after machining, Chrysler would measure what the final bore size ended up at, and write the corresponding letter indicating that size on the side of the block. Although these were painted over in final assembly, after hot tanking a block they are usually still visible after the paint is removed. This is a picture of an NOS warranty short block which never got painted with normal engine paint, so you can clearly see the letters marked on the side. You can also see where they wrote the letters on the top of the pistons with black ink.

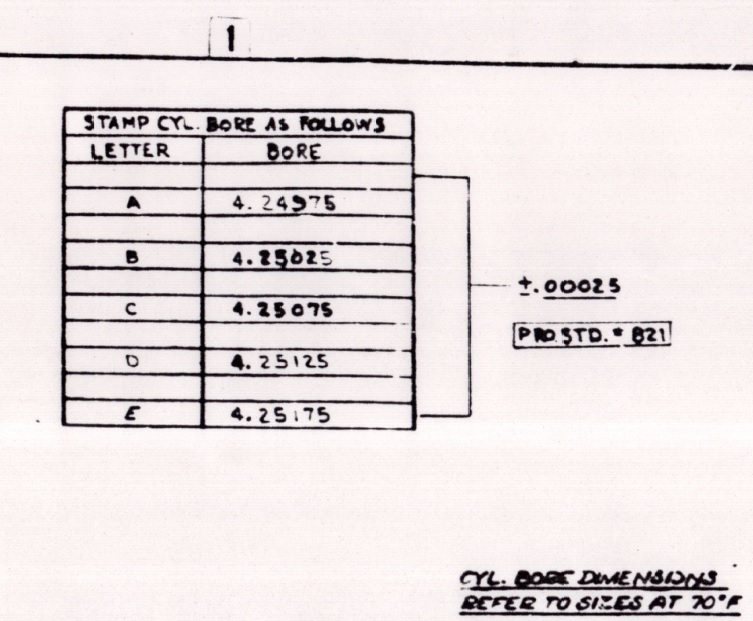

This is a section from Chrysler's original 383 Engine block technical drawings, showing the instructions on how to stamp the block with the cylinder bore dimensions. Basically, every half of a thousandth of an inch bigger gets you to the next letter.

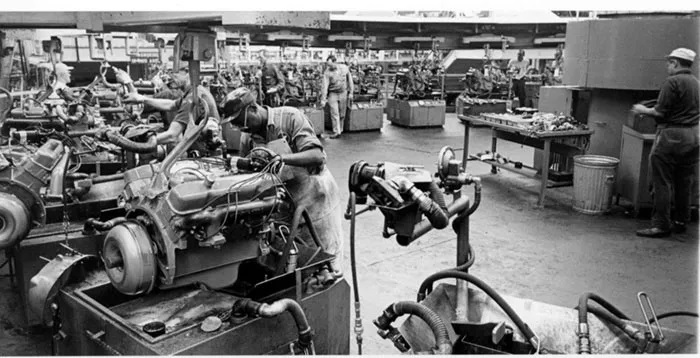

After short block assembly, engines were balanced completely assembled, including with the torque converter attached.

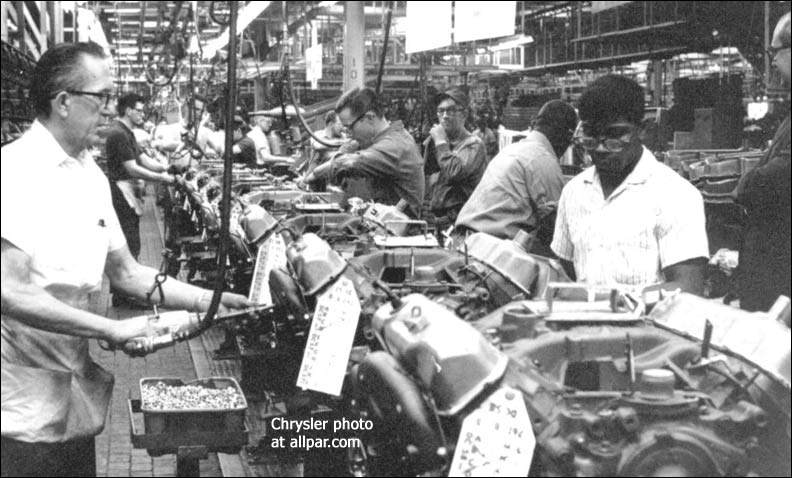

Once short blocks were complete and heads were assembled, engines went into the final assembly line.

Notice the bins full of parts on the right side of the picture.

Attaching exhaust manifolds (above.) You might recognize these as the high performance manifolds from 1968-69.

Attaching intake manifolds (above.)

Notice the second engine back is actually a heavy duty truck 413 engine. These have the huge water pump and cylinder heads on them.

And finally, valve covers are torqued (all 6 bolts at once) by these automated machines.

After final assembly, engines went through the "merry-go-round." This was a circular arrangement of 24 "production test stands" where the engines could be hot tested and checked for leaks or other problems.

Trenton also had 9 actual dynometers used for product engineering. 8 of them were rated up to 600 horsepower and one was rated at 350 horsepower.

Here's a closeup of a merry go round station.

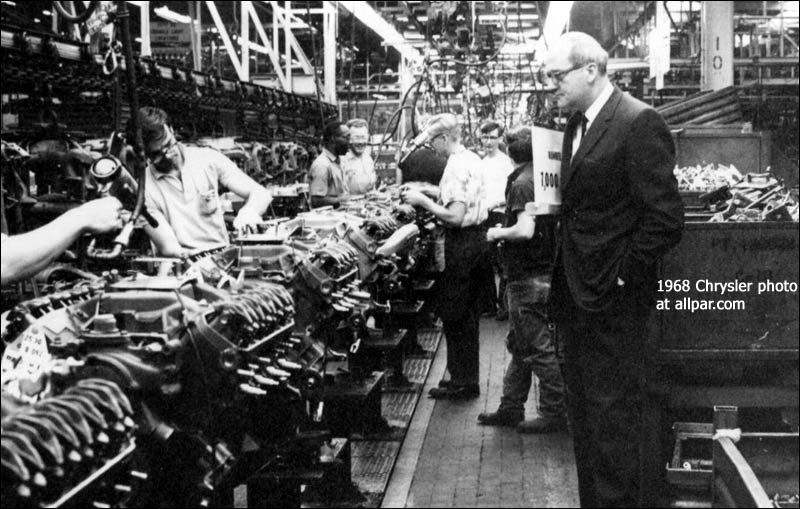

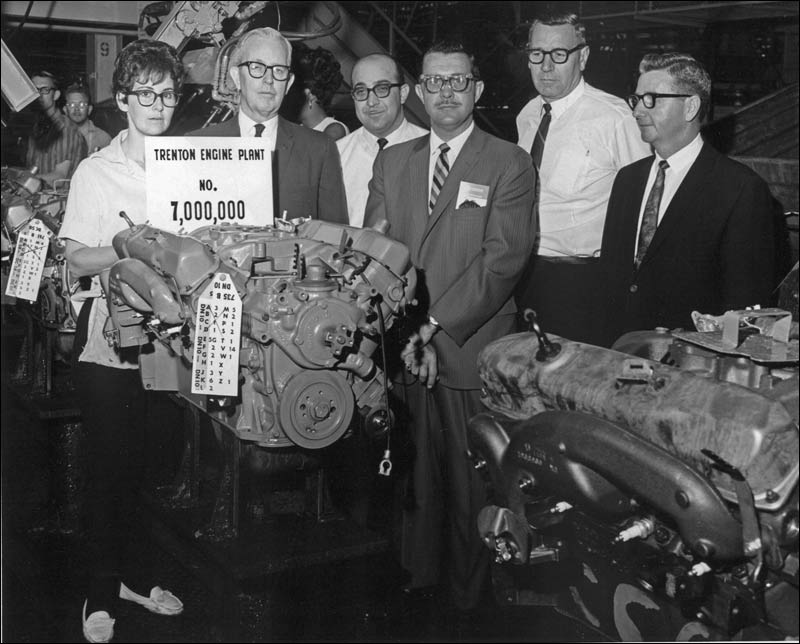

In the late 60's, Trenton celebrated their 7 millionth engine. It's been said that overall, Trenton made 750,000 440's and over 3 million 383's.

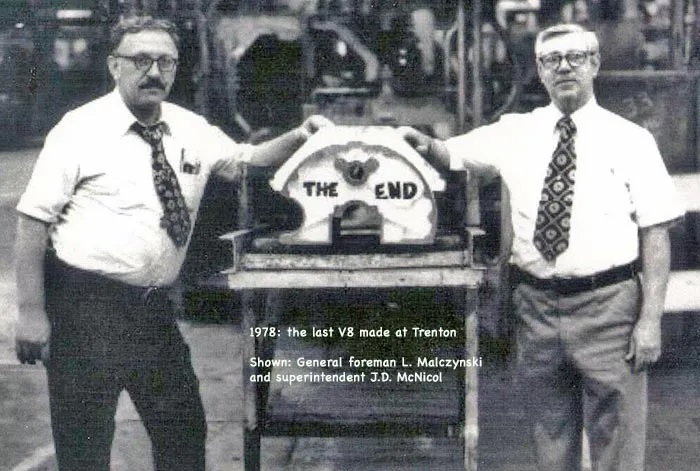

And, in the end, the last 440 was made on September 29th, 1978. The end of an era.

And, all those hard working folks have to eat! Here's Trenton's cafeteria.

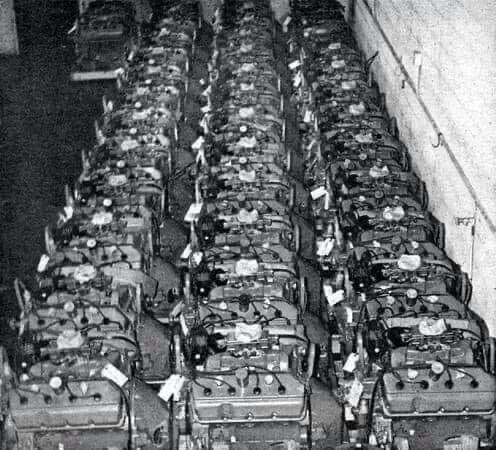

And when your boss tells you "Whatever you do, don't open that door at the end of the hall..." It might be because it leads to a storage room like this...

Hope you enjoyed this historic tour, support our work at: